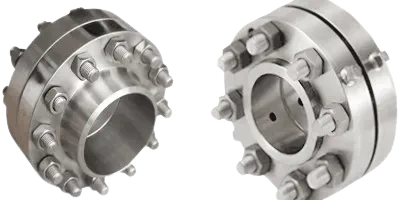

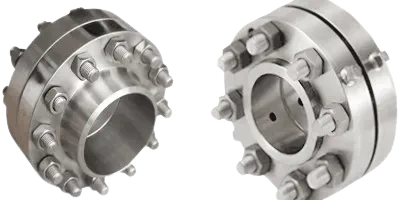

Alloy Steel Orifice Flanges Manufacturer and Supplier In India

Naysha Steel is a prominent manufacturer and supplier of alloy steel orifice flanges in Mumbai, India. With a strong focus on quality and precision, they offer a wide range of flanges designed for various industrial applications. Their products are crafted using premium-grade alloy steel, ensuring durability and excellent performance. With a commitment to customer satisfaction, Naysha Steel delivers reliable and accurate solutions, meeting international standards. Their expertise, coupled with state-of-the-art manufacturing facilities, makes them a trusted choice for clients seeking high-quality orifice Alloys Steel flanges manufacturer in India.

Types of Alloy Steel Orifice Flanges

Raised face orifice flanges are widely used in applications where a secure and leak-free connection is essential. They are primarily used in applications where the flange needs to be bolted directly to a flat surface or when a gasket is not required. The orifice plate is installed between the flanges, and the assembly is welded to the pipeline. These flanges are commonly used in high-pressure and high-temperature applications. They are easy to install and provide a smooth flow path through the orifice plate.

- Socket Weld Flanges (SW): These flanges have a socket-like end that fits over the pipe and is welded to provide a strong and leak-resistant joint.

- Slip-On Flanges (SO): Slip-on flanges have a flat face and are slipped over the pipe before being welded in place.

- Weld Neck Flanges (WN): Weld neck flanges have a long tapered hub that provides reinforcement to the flange and strengthens the joint.

- Blind Flanges (BL): Blind flanges are solid discs that are used to seal off the end of a pipe system.

- Threaded Flanges (TH): Threaded flanges have internal threads that allow them to be screwed onto the pipe.

Features of Alloy Steel Orifice Flanges

- Alloy Steel socket weld Alloy Steel flanges are made from high-quality Alloy Steel, which provides excellent resistance to corrosion, oxidation, and high temperatures.

- Socket weld flanges offer a strong and secure joint. The socket-like end of the flange fits over the pipe, and the connection is welded, providing a robust and leak-resistant connection.

- Alloy Steel socket weld Alloy Steel flanges are available in various sizes, pressure ratings, and configurations, making them suitable for a wide range of applications across different industries.

- These flanges are compatible with a wide range of piping systems, allowing for seamless integration and easy installation.

- Alloy Steel socket weld Alloy Steel flanges are designed to withstand high-pressure and high-temperature conditions, making them suitable for demanding applications in industries such as oil and gas, chemical processing, and power generation.

Size of

Alloy Steel Orifice Flanges

| Nominal Size |

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. of Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

Uses of Alloy Steel Orifice Flanges

Alloy Steel socket weld Alloy Steel flanges are extensively used in the oil and gas industry for piping systems, including upstream exploration and production, refining, and transportation. They are suitable for handling corrosive fluids, high pressures, and challenging operating conditions. Petrochemical plants require flanges that can withstand aggressive chemicals and high temperatures.

Quality of Alloy Steel Orifice Flanges

High-quality Alloy Steel Steels with appropriate chemical compositions are chosen for manufacturing socket weld Alloy Steel flanges. These Alloy Steel offer excellent corrosion resistance, mechanical strength, and temperature resistance, ensuring long-term performance and reliability. Alloy Steel socket weld Alloy Steel flanges are produced in adherence to international standards such as ANSI/ASME, ASTM, and DIN.

Alloy Steel Orifice Flanges Manufacturer : Grades & Classes

- Grade F5

- Grade F9

- Grade F11

- Grade F22

- Grade F91

- Class 150

- Class 300

- Class 600

- Class 900

- Class 1500

- Class 2500

Please find below our manufacturing and Sales network below: (Contact us for detailed information for your nearest branches)

- Alloy Steel Orifice Flanges manufacturer and contractor in Hyderabad

- Alloy Steel Orifice Flanges manufacturer and supplier in Chennai

- Alloy Steel Orifice Flanges manufacturer and stockists in Pune

- Alloy Steel Orifice Flanges manufacturer and dealer in Faridabad

- Alloy Steel Orifice Flanges manufacturer and warehousing in Chandigarh

- Alloy Steel Orifice Flanges manufacturer and wholesalor in Delhi

- Alloy Steel Orifice Flanges manufacturer and trader in Coimbatore

- Alloy Steel Orifice Flanges manufacturer and stockholder in Bangalore

Industries served by Alloy Steel Orifice Flanges

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report