Stainless Steel Weld Neck Flanges Manufacturer and Supplier In Bangalore

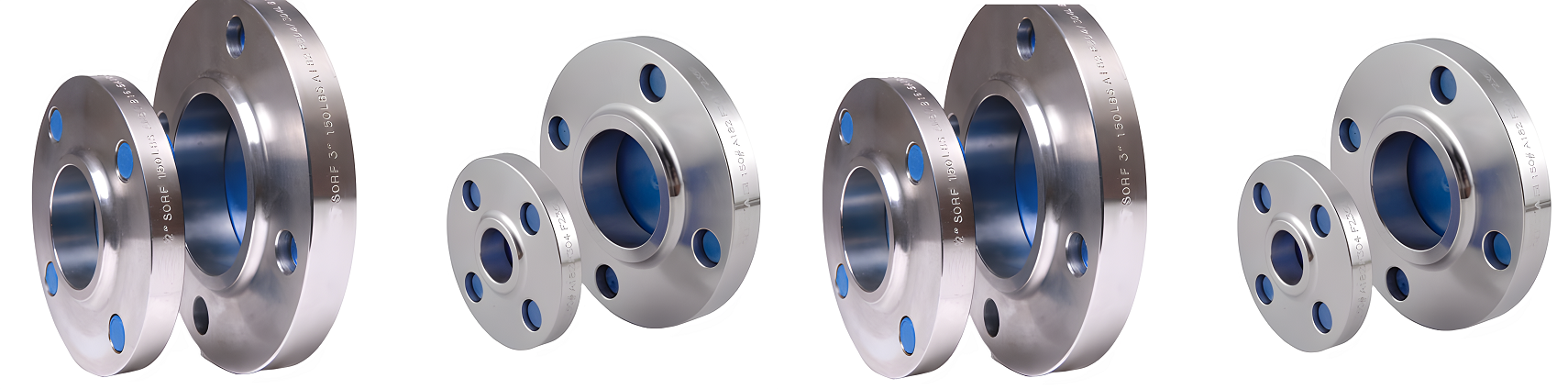

A flange that is welded to the end of a pipe is known as a weld neck flange. It is specifically designed and produced to provide a strong and leak-proof connection, making it ideally perfect for high-pressure and high-temperature operations. The weld neck flange has a long neck or short neck that adds new support and strength to the pipe. This design aids in stress reduction at the weld joint, preserving the structural integrity of the flange. These stainless steel weld neck flanges are designed to help companies securely join pipes, valves, and other items without leakaging problems. These include oil and gas companies, chemical plants, and even power plants! These flanges are available in a variety of lengths and widths, as well as special flat surface configurations. The weld neck flanges have narrow openings high on the sides in smaller sizes than larger ones.

Stainless Steel Weld Neck Flanges Manufacturer And Dealer in Bangalore

Naysha Steel and Alloys, based in Mumbai, India, is a leading manufacturer and supplier of superier brand weld neck flanges. Stainless steel weldneck flanges are frequently used in the oil and gas industry to connect pipes, valves, and gear at oil refineries. They're also useful for pipelines or platforms that work far from land - its all part of the same industry! These flange type connectors are well-known for their sturdy construction, high strength, and resistance to rust, ash, and heat. We are very concerned with the quality of our work and thats why it is critical to us that our products are not only good, but also exceed your expectations. Naysha Steel and Alloys remains the industry leader as we continue to improve. We always make strong ss weld neck flanges that are difficult to beat when it comes to quality and safety.

Advantages of Stainless Steel Weld Neck Flanges

Weld neck flanges offer several advantages over other types of flanges, making them a popular

choice in colorful diligence. Then are some crucial benefits of using weld neck flanges

- 1.Strength and continuity: The use of pristine sword blends in manufacturing

weld neck flanges provides them with high strength and continuity, making them suitable for

demanding operations.

- 2. Leak- Resistant Design The long neck and consistence of weld neck flanges

allow for a larger weld area, performing in better sealing performance and reduced threat of

leakage.

- 3.Smooth Flow TransitionThe extended neck of weld neck flanges ensures a

smooth transition from the pipe to the outfit, minimizing turbulence and pressure drop.

- 4.Versatility: Weld neck flanges can be used in a wide range of operations,

including chemical processing, petrochemical processing, power generation, oil painting and gas

product, water and wastewater treatment, marine and coastal operations, aerospace, and defense.

ASME B16.5 Weld Neck Flanges: Stainless Steel 304 weld neck flanges and Stainless Steel 316 weldneck, ANSI Class 150 weld neck flanges and ANSI 300# weld neck flanges Manufacturer And Supplier In Bangalore

Naysha Steel and Alloys manufactures some of the best weldneck flanges that are strong, long-lasting, and perform admirably. Our Flange parts are made of a variety of materials, including stainless steel, carbon steel, and others. These can also be copper or an alloy. We also use hastelloy to make them strong enough for the work that these heavy projects require.

Weldneck flanges play an important role in many commercial applications. They provide a secure and leak-free connection between pipes. These flanges are designed to withstand high pressure and heat. They are ideal for high-stress tasks in industries such as oil, gas, and chemicals, as well as power generation. In the below paragraph you will find the key components and benefits of weldneck flanges. We will also provide helpful support on how to properly set them up and care for them as a complimentary support to our clients.

At Naysha Steel and Alloys, we want to provide good flanges that are just right for what our customers need. They use the newest tech. and tools to make flanges that are accurate, trustworthy, and strong. These intermediate components gain their prominence because of their versatility. With applications in industrial pipelines, chemical plants or building huge projects, the stainless steel weld neck elbow joints ensure reliability, durability and even a touch of engineering artisty. Naysha Steel and Alloys is a top producer, and we are known for making high-quality weld neck flanges in Bangalore, India. Our company makes all type of stainless steel flanges that are very important in oil and gas industry's. We help connect pipes, valves, and other equipment smoothly for things like refineries without any problems with our SS Weldneck Flanges. Also, these flanges are very helpful for uses related to pipes and platforms in the sea. We make them useful even in far-off places that do not have easy access to onshore services.

Available sizes of ss weld neck flanges in Bangalore (Bengaluru):

| Nominal Size |

Outside Diameter

(OD) |

Min. Thickness

(T) |

RF Dia.

(R) |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle

(BC) |

SO Bore ID

(SB) |

WN Bore ID

(WB) |

Dia. Hub Base

(HB) |

Dia. of Hub Top

(HT) |

SO LTH

(SL) |

WN LTH

(WL) |

| 1⁄2 |

3.50 |

0.38 |

1.38 |

4 |

0.62 |

2.38 |

0.88 |

0.62 |

1.19 |

0.84 |

0.56 |

1.81 |

| 3⁄4 |

3.88 |

0.44 |

1.69 |

4 |

0.62 |

2.75 |

1.09 |

0.82 |

1.50 |

1.05 |

0.56 |

2.00 |

| 1 |

4.25 |

0.50 |

2.00 |

4 |

0.62 |

3.12 |

1.36 |

1.05 |

1.94 |

1.32 |

0.62 |

2.12 |

| 11⁄4 |

4.62 |

0.56 |

2.50 |

4 |

0.62 |

3.50 |

1.70 |

1.38 |

2.31 |

1.66 |

0.75 |

2.19 |

| 11⁄2 |

5.00 |

0.62 |

2.88 |

4 |

0.62 |

3.88 |

1.95 |

1.61 |

2.56 |

1.90 |

0.81 |

2.38 |

| 2 |

6.00 |

0.69 |

3.62 |

4 |

0.75 |

4.75 |

2.44 |

2.07 |

3.06 |

2.38 |

0.94 |

2.44 |

| 21⁄2 |

7.00 |

0.81 |

4.12 |

4 |

0.75 |

5.50 |

2.94 |

2.47 |

3.56 |

2.88 |

1.06 |

2.69 |

| 3 |

7.50 |

0.88 |

5.00 |

4 |

0.75 |

6.00 |

3.57 |

3.07 |

4.25 |

3.50 |

1.12 |

2.69 |

| 31⁄2 |

8.50 |

0.88 |

5.50 |

8 |

0.75 |

7.00 |

4.07 |

3.55 |

4.81 |

4.00 |

1.19 |

2.75 |

| 4 |

9.00 |

0.88 |

6.19 |

8 |

0.75 |

7.50 |

4.57 |

4.03 |

5.31 |

4.50 |

1.25 |

2.94 |

| 5 |

10.00 |

0.88 |

7.31 |

8 |

0.88 |

8.50 |

5.66 |

5.05 |

6.44 |

5.56 |

1.38 |

3.44 |

| 6 |

11.00 |

0.94 |

8.50 |

8 |

0.88 |

9.50 |

6.72 |

6.07 |

7.56 |

6.63 |

1.50 |

3.44 |

| 8 |

13.50 |

1.06 |

10.62 |

8 |

0.88 |

11.75 |

8.72 |

7.98 |

9.69 |

8.63 |

1.69 |

3.94 |

| 10 |

16.00 |

1.12 |

12.75 |

12 |

1.00 |

14.25 |

10.88 |

10.02 |

12.00 |

10.75 |

1.88 |

3.94 |

| 12 |

19.00 |

1.19 |

15.00 |

12 |

1.00 |

17.00 |

12.88 |

12.00 |

14.38 |

12.75 |

2.12 |

4.44 |

| 14 |

21.00 |

1.31 |

16.25 |

12 |

1.12 |

18.75 |

14.14 |

13.25 |

15.75 |

14.00 |

2.19 |

4.94 |

| 16 |

23.50 |

1.38 |

18.50 |

16 |

1.12 |

21.25 |

16.16 |

15.25 |

18.00 |

16.00 |

2.44 |

4.94 |

| 18 |

25.00 |

1.50 |

21.00 |

16 |

1.25 |

22.75 |

18.18 |

17.25 |

19.88 |

18.00 |

2.62 |

5.44 |

| 20 |

27.50 |

1.62 |

23.00 |

20 |

1.25 |

25.00 |

20.20 |

19.25 |

22.00 |

20.00 |

2.81 |

5.62 |

| 22 |

29.50 |

1.75 |

25.25 |

20 |

1.38 |

27.25 |

22.22 |

21.25 |

24.25 |

22.00 |

3.07 |

5.82 |

| 24 |

32.00 |

1.81 |

27.25 |

20 |

1.38 |

29.50 |

24.25 |

23.25 |

26.12 |

24.00 |

3.19 |

5.94 |

ASME B16.5 Flanges: SS 304 and SS 316, ANSI Class 150 and ANSI Class 300 Availablity In Bangalore

Weld neck flanges are carefully made to create a strong and lasting link with welding, making sure

they have enough strength that lasts forever. The special weld neck design of these fittings makes it

easy to connect pipes. This greatly lowers the chance that fluids will leak or escape. This design not only

makes the structure stronger but also reduces chances of stopping work because there might be fluid

leaking.

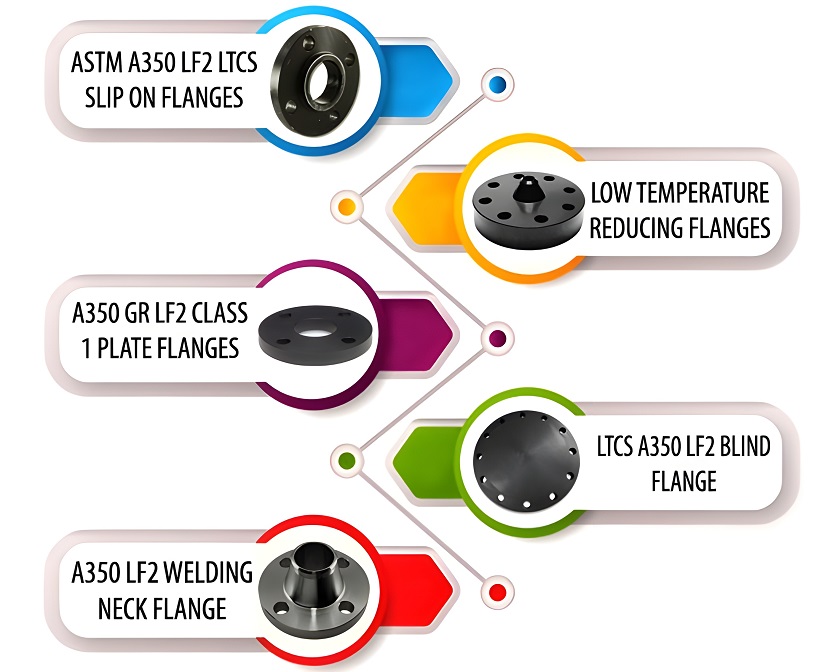

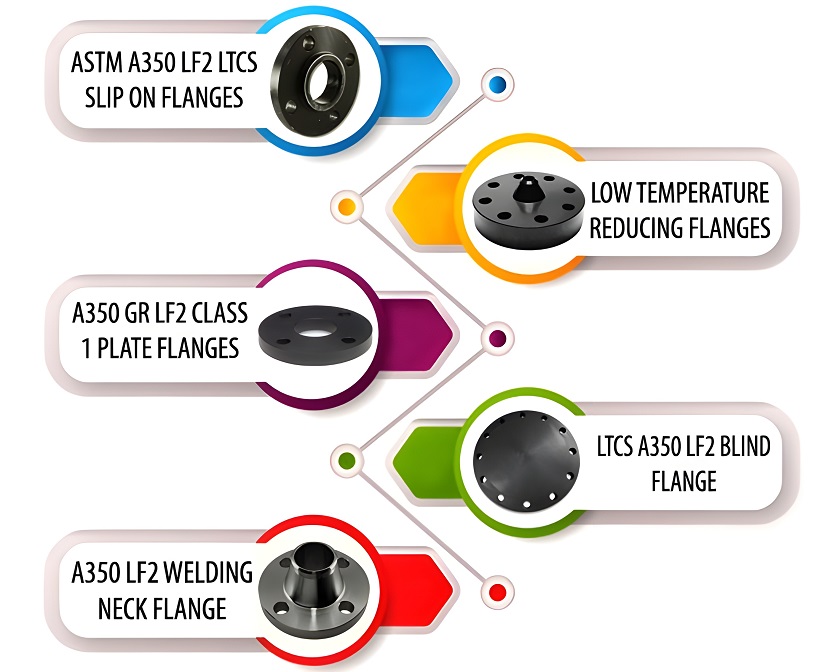

At Naysha Steel and Alloys, we are happy to provide many types of weld neck flanges for different

needs in various industries. Our flanges come in different types. They include common, long and small

sizes with big hubs, as well as those that can be made smaller. This makes them good for many different

projects needs you might have! Whether you want normal solutions or special choices, Naysha Steel

and Alloys has the knowledge to help with your one-of-a-kind needs for welding neck flanges. We have a wide

range of other products offered too related to SS Weldenck flanges in Bangalore.

Naysha Steel and Alloys is a top supplier who gives more than standard flange sizes. We have many types

of weld neck flanges made from SS, hastelloy, etc for long time and nickel alloy

steel with special features like inconel materials to make them extra strong. These things are picked

because they last really long and can be trusted. They're perfect for uses with lots of pressure or

very hot engineering sites. Businesses like oil and gas companies and gulf companies need strong bonds. Our flanges help them work well in such places, making sure they don't have problems during their operations. Naysha Steel and Alloys is dedicated to giving a product that matches the tough needs of high-pressure, hot use cases and strong bonds.

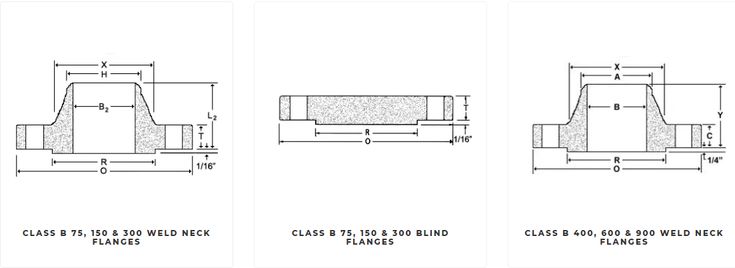

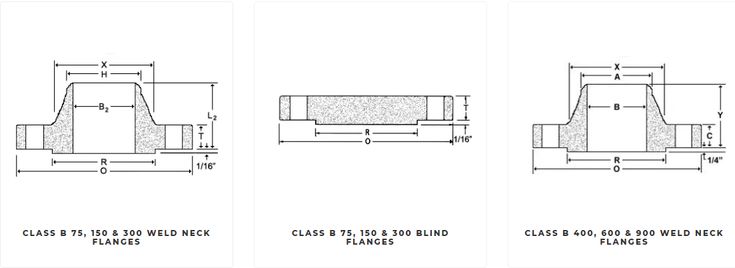

Understanding of Weld Neck Flange Dimensions

Naysha Steel and Alloys is a well-known company. They provide lots of different sizes for their

stainless steel weld neck flanges, which can be used in many industries. Our catalog has lots of

different sizes. This makes it easy to choose what you need, from 1/2" inches up to 80" +

inches or even more if needed. This big size range shows we are dedicated to giving answers that

fit well with many pipe systems. This helps make our solutions flexible and useful for a lot of

uses. Our stainless steels weld neck flanges are made very carefully from top-notch quality stainless

steel materials. This shows how much we care about making good products. Picking strong

materials not only makes things last a long time, but they also protect against rust and wear

down from heat. Naysha Steel and Alloys' stainless steel weld neck flanges are made strong to

handle tough places. They're good for important tenders/infrastructure where things have to work right all the

time and last a long time.

In the world of water systems and pipes, strong links are very important, You can't say it

enough times. Naysha Steel and Alloys knows this requirements, We give solutions by offering different

stainless steel weld neck flanges that help make industrial businesses better in stability and

how they work. Believe Naysha Steel and Alloys for stainless steel weld neck flanges. We not

just meet standards but go beyond them, making sure a strong and long-lasting link is set in

every use.

Chemical Composition Table

| Grade/ Marked Symbol |

Carbon (Max) |

Manganese (max) |

Silicon (maximum) |

Phosphorus (max) |

Sulfur (max) |

Chromium |

Molybdenum |

Nickel |

N |

| F304 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

18-20

|

- |

8-11

|

- |

| F304L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

18-20

|

- |

8-13

|

- |

| F316 |

0.08 |

2 |

0.75 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

64.845 |

| F316L |

0.035 |

2 |

1.00 |

0.045 |

0.030 |

16-18

|

2-3

|

10-14

|

68.89 |

SS Weld NecK Flanges Pricelist in bangalore

| WNRF FLANGES ASTM A182 F304 B16.5 150#

SCH-40S Price |

| Size |

Aprox. Wt/Unit |

FOB INR |

CIF INR |

FOB USD |

CIF USD |

FOB STGP |

CIF STGP |

FOB EURO$ |

CIF EURO$ |

| 15mm |

0.54 |

543.95 |

591.25 |

8.242 |

8.958 |

5.551 |

6.033 |

9.890 |

10.750 |

| 20mm |

0.78 |

854.45 |

928.75 |

12.946 |

14.072 |

8.719 |

9.477 |

15.535 |

16.886 |

| 25mm |

1.12 |

1009.70 |

1097.50 |

15.298 |

16.629 |

10.303 |

11.199 |

18.358 |

19.955 |

| 32mm |

1.47 |

1179.90 |

1282.50 |

17.877 |

19.432 |

12.040 |

13.087 |

21.453 |

23.318 |

| 40mm |

1.90 |

1475.45 |

1603.75 |

22.355 |

24.299 |

15.056 |

16.365 |

26.826 |

29.159 |

| 50mm |

2.77 |

1707.75 |

1856.25 |

25.875 |

28.125 |

17.426 |

18.941 |

31.050 |

33.750 |

| 65mm |

4.49 |

2717.45 |

2953.75 |

41.173 |

44.754 |

27.729 |

30.140 |

49.408 |

53.705 |

| 80MM |

5.44 |

3105.00 |

3375.00 |

47.045 |

51.136 |

31.684 |

34.439 |

56.455 |

61.364 |

| 100mm |

7.69 |

4347.00 |

4725.00 |

65.864 |

71.591 |

44.357 |

48.214 |

79.036 |

85.909 |

| 125mm |

9.40 |

7452.00 |

8100.00 |

112.909 |

122.727 |

76.041 |

82.653 |

135.491 |

147.273 |

| 150mm |

11.82 |

9315.00 |

10125.00 |

141.136 |

153.409 |

95.051 |

103.316 |

169.364 |

184.091 |

| 200mm |

19.11 |

13972.50 |

15187.50 |

211.705 |

230.114 |

142.577 |

154.974 |

254.045 |

276.136 |

| 250mm |

26.19 |

18630.00 |

20250.00 |

282.273 |

306.818 |

190.102 |

206.633 |

338.727 |

368.182 |

Get an estimate within 10 minutes!

Flange Welding Neck ANSI 150, IS6392 Weld Neck Flanges, Weld Neck Stainless Steel Flanges

Manufacturer, UNS S31803 Weld Neck Flanges Stockist, UNS S31803 Weld Neck Flanges Manufacturers,

UNS

S31803 Weld Neck Flanges Exporter, UNS S32205 Weld Neck Flanges Stockist : Grades & Classes

- ASTM A182 F304/F304L: Standard austenitic stainless steel grade.

- ASTM A182 F316/F316L: Austenitic stainless steel with enhanced corrosion

resistance.

- ASTM A182 F321/F321H: Stabilized stainless steel grade with titanium addition.

- ASTM A182 F347/F347H: Stabilized stainless steel grade with niobium addition.

- ASTM A182 F51: Duplex stainless steel grade with high strength and corrosion resistance.

- ASTM A182 F53: Super duplex stainless steel grade with excellent corrosion resistance.

- Class 125: Class 125 Weld Neck Flange suitable for aggressive conditions.

- Class 150: Weld neck flange design for low-pressure applications.

- Class 300: Flanges suitable for moderate-pressure applications.

- Class 600: Weld Neck Flange Class 600 designed for high-pressure applications.

- Class 900: Flanges suitable for very high-pressure applications.

- Class 1500: Flanges designed for extremely high-pressure applications.

Flange Welding Neck 150, 18 300 Class SCH 80 Weld Neck Flange, Class 150 Weld Neck Flange SCH

80,

Welding Neck Flanges SCH 40, SS Weld Neck Flanges Specifications

| Specification Of : |

Weld Neck Stainless Steel Flanges |

| JIS Standards |

5K, 10K, 40K, 16K 20K 30K, 63K |

| Size Of Bore Diameter Flange |

NPS ≤ 10 |

| Manufacturer Of Standard Dimensions |

EN-1092 Flange, ASME B16.48 Flange, API605 Flange, BS4504 Flange, EN1092 Flange, UNI

Flange, ISO Flange, API7S-43 Flange, ANSI/ASME B16.5 Flange, API7S-15 Flange, MSS

S44

Flange, IS 2062 Flange, ASME B16.36 Flange, DIN Flange, AWWA C207 Flange, B16.47

Series

A & B Flange, BS1560-3.1 Flange, ISO70051 Flange, API Flange, ASME Code for 12 inche

Welding Neck Flanges.

|

| Minimum Pressure |

150# To 2500# |

| Flange Face Type |

Raised Face, Groove And Small Tongue Groove, RTJ, Weld Neck Flanges Flat Face, Large

Tongue & Large

Male-Female And Small Male-Female, Lap-Joint Face. |

| Top Six Type Of Flanges |

Threaded, Lap Joint, Socket-Weld, Blind, Slip-On or Weld Neck Flanges

|

| Standard Materials |

Duplex Steel & Super Duplex Steel, Copper Nickel, Wrought Iron, Inconel, Mild Steel,

Stainless Steel, Hastelloy, Cast Iron, Alloy Steel, Carbon Steel.

|

| Thickness Length |

NPS ≤ 18

|

| Welding neck flanges size |

(1/2") To (48")

|

| Manufacturing Process |

Forged/ Machined/ Heat Treated

|

| Other Type Of Flange |

Forged/ Plate/ Threaded

|

| Application |

Oil And Gas Industry

Power Plants Industry

Food Processing And Manufacturing

Waterworks Systems

Fossil Fuel Power Plants

Nuclear Power Application

Municipal Pipe Systems

|

Please find below our other manufacturing and Sales network near bangalore, Karnataka

: (Contact us for detailed information for your nearest branches)

- Stainless Steel Weld Neck Flanges manufacturer and contractor in Mysore

- Stainless Steel Weld Neck Flanges manufacturer and supplier in Davangere

- Stainless Steel Weld Neck Flanges manufacturer and stockists in Gulbarga

- Stainless Steel Weld Neck Flanges manufacturer and dealer in Mangalore

- Stainless Steel Weld Neck Flanges manufacturer and warehousing in Hubli

- Stainless Steel Weld Neck Flanges manufacturer and wholesalor in Manipal

Frequently Asked Questions

What is a stainless steel weldneck flange?

A stainless steel weldneck flange is a type of pipe flange designed to be welded onto the

neck of a pipe. It provides a smooth, high-strength connection for joining pipes,

valves,

and other equipment.

What types of stainless steel material grades are used for weldneck flanges?

Common stainless steel materials include 304, 316, and 321, among others. The choice of

stainless steel grade depends on the specific application and the required corrosion

resistance.

What sizes are available for stainless steel weldneck flanges?

Stainless steel weldneck flanges are available in a wide range of sizes, typically

ranging from 1/2 inch to several feet in diameter. The size you need depends on your specific

piping system requirements. All the standard Flange dimensional sizes are Readily available at any Naysha Steel branch in Bangalore.

Can stainless steel weldneck flanges be used with other pipes?

Yes, stainless steel weldneck flanges can be used with pipes made of other materials,

provided the flange material is compatible with the pipe material, and the connection is

properly sealed.

Industries served by Stainless Steel Weld Neck Flanges In Bangalore

In the oil and gas industry, blind Alloy Steel flanges are used in pipelines, storage tanks, and offshore platforms. They are employed for closing off openings during maintenance, repair, or when a branch connection is not required. Petrochemical plants utilize blind Alloy Steel flanges in equipment such as reactors, distillation columns, and storage vessels. These flanges provide a secure and leak-proof seal when closing off unused openings or isolating sections of the process.

Oil and Gas Industries

The oil and gas industry includes a wide range of from drilling and

production to refining and marketing. Some of the major players in this

include oil and gas companies, service providers, equipment.

Petroleum Industries

In the drilling process, stainless steel is used to make drill bits, pipes, and other

equipment that must withstand high pressures and temperatures. Stainless steel is

also used to make pumps, valves, and fittings for the transportation.

Shipbuilding in India

In storage applications, stainless steel is used to make tanks and containers that

can safely store corrosive and hazardous chemicals. It is also used in piping

systems for chemical transfer and distribution chemical industry.

Marking & Pricing

Products are packaged to ensure that there is no damage during of goods transport. In case of exports, standard export packaging is done with utmost care in wooden covering or boxing. All products are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make

customized marking on our products.

Quality Assurance

At Naysha Steel, all fittings and flanges are subject to strict inspection at each and every stage of the production process, from starting material

purchasing to product dispatch. They are visually examined for compliance to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards.

Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality compliance

of products.

Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report